Our biogas to biomethane membrane technology

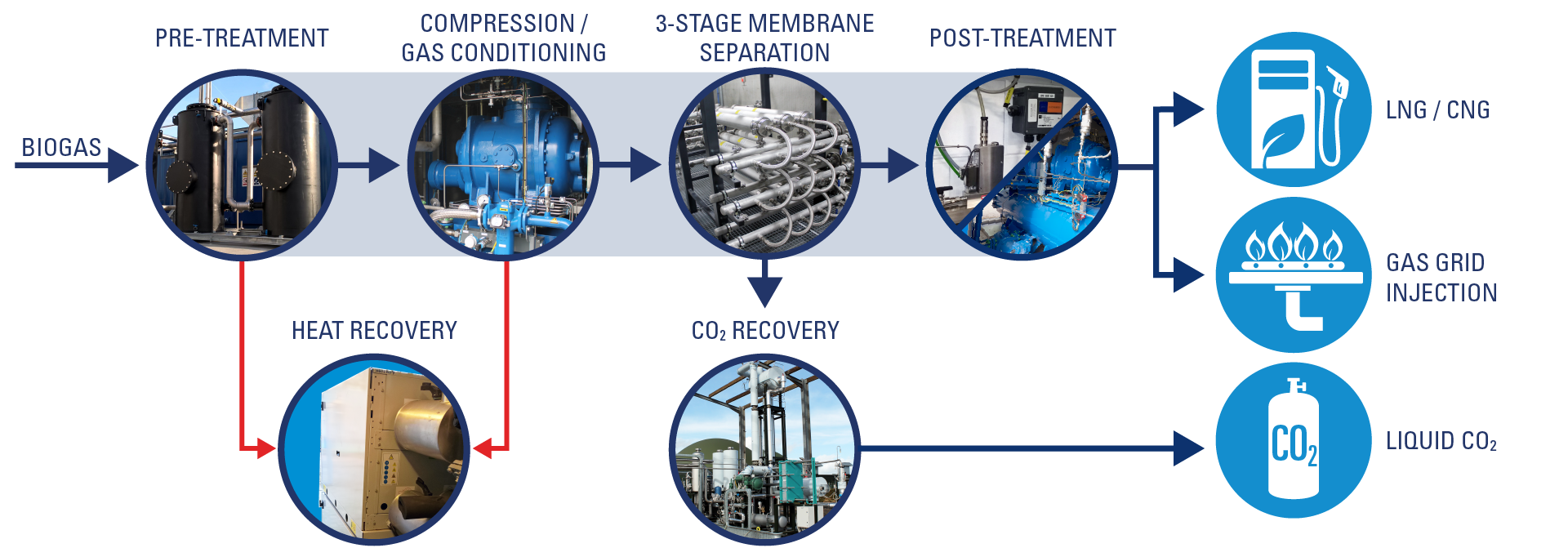

For the upgrading of biogas to biomethane with the desired methane content, Bright Renewables applies the proven membrane technology capable of achieving more than 97% operational availability. How it works? Watch the video and learn in 3 minutes or keep on reading.

Separation by membranes

Bright’s biogas upgraders are compact and modular and contain a membrane unit. In this membrane technology unit, the gas is separated by means of an imposed pressure difference over the membrane. Two gas streams will be obtained from the plant; a product gas with a high methane value and a CO2 rich gas. Using membranes with high separation efficiency allows recovery of the highest possible methane yield. Depending on the grid or user requirements, the gas can be upgraded to the preferred methane concentration.

Learn about our CO2 liquefaction / recovery technology to recover the CO2 of the biogas upgrading process producing liquefied bio-CO2.